Discover Turkey’s Top Modular Building Solutions

The changes, developments and events that the world around us has witnessed in recent decades have imposed pivotal transformations on the construction sector, making some construction methods the dominant ones for many reasons. For example, some countries may witness natural disasters and armed conflicts, which have highlighted the need to search for fast, flexible and environmentally friendly construction methods at the same time. If you are intending to invest as a developer and you need the fastest building method, there is no more appropriate method than Modular building systems to achieve your goals and keep pace with what is happening around the world. Even if you have your own land and want it to be ready for you and your family in the shortest time, you’ll find what you’re looking for in this blog.

Not to mention that Modular building systems have been used for decades for many purposes, such as construction sites or some areas that require speed and flexibility in the construction method.

The construction landscape in Turkey has been reshaped in response to the rapidly changing environment around us and in line with advanced technologies that focus on sustainability and environmental conservation as a primary goal, in addition to speed and flexibility as building pillars using Modular building systems. Thus, you should hunt this great opportunity to achieve your aim wither you plan to proceed with a developer business or build your own home in a smart way.

Read also: Two storey prefabricated houses cost in Turkey

In this blog you’ll know all about Modular Construction so you can make the right decision.

Blog content:

- Modular Construction: flexibility for whom they are flexible

- Custom mobile homes could really your absolute best choice

- The Two Types of modular building systems

- What building materials are used in modular building systems

Modular Construction: flexibility for whom they are flexible

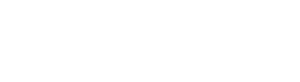

These are buildings that are manufactured off-site in specialized factories and then transported to construction sites for assembly. Although this method has been used for decades, Modular building systems are increasingly being used for many purposes such as offices, hotel buildings, residential purposes, and more.

In Turkey, the reliance on Modular building systems has increased due to the strong trend towards greater reliance on advanced building materials such as steel and engineered wood. In addition to advanced manufacturing technologies such as 3D printing and automated assembly, which makes it possible to produce highly precise components with the highest quality.

Do you know that statistics predict that the Turkish construction market via Modular building systems will reach $ 1.5 billion by 2025? and with an expected CAGR of 15% between 2023 and 2028, it’s indicating the steady growth of the industry and its potential. So never miss this chance and start now to make your dreams true. You would call us and know more about how to start from here.

Custom mobile homes could really your absolute best choice

If you are still not sure about Modular building systems and custom mobile homes advantages, lets add more spices to your dish with some of the benefits you should gain:

– Bad weather conditions cannot be an obstacle to the completion of the project, as 60 to 90% of the building work is done inside the factory. On this basis, project delays can be largely avoided.

– Controlling the supply of raw materials and building materials inside the factory allows for reducing waste and thus reducing costs, as the savings in raw materials in Modular building systems are estimated at 90% less than other construction methods.

– Modular building systems allow for a significant amount of time savings as the manufacturing of buildings can proceed while working on the foundations.

– Modular building systems are very suitable for remote locations where on-site construction may be difficult or expensive. The ability to build away from these locations also means that employees can work in places where medical and health care are more easily available if necessary.

– Buildings created by Modular building systems can be modified very easily, whether by adding units, moving from one place to another, or renovating.

– Many buildings constructed by Modular building systems use lightweight, durable insulated panels that provide self-contained thermal insulation as well as resistance to moisture and cold when compared to materials such as wood. Building manufactured by Modular building systems also provides the ability to retain high levels of moisture within the building, improving product quality.

The Two Types of modular building systems

We know that you have something in your mind about the purpose of building custom mobile homes. Whatever it Was in your mind we’ll get aligned with it by offering two types of modular building systems.

Permanent modular construction

This construction is a permanent structure and will not be moved according to the owner’s needs. Therefore, Permanent modular construction is best suited for unit occupants who plan to reside for a long period of time in one fixed location.

Examples of Permanent modular construction includes healthcare facilities, hotels, multi-family housing, and K-12 educational facilities.

Read also: What’s the Buzz About Light Steel Homes in Turkey?

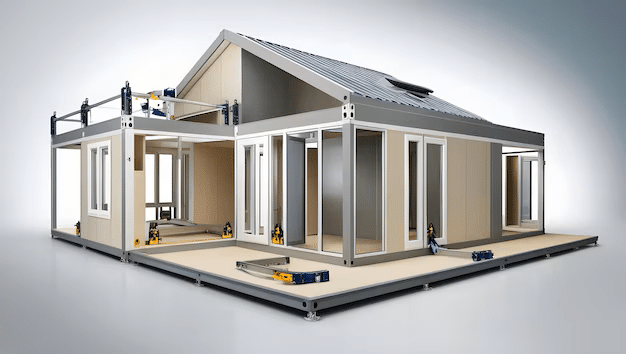

Relocatable Buildings

Transportable buildings involve the construction of partial or complete units off-site in a controlled factory environment. These units are then delivered according to the owner’s needs and can be moved to different locations. Therefore, occupants of buildings who plan to stay for a short or temporary period in one place and move to different locations are best suited for this type of construction. Examples of transportable or portable buildings include classrooms, offices, emergency/disaster relief housing structures, etc.

What building materials are used in modular building systems?

Wither you are / aren’t a professional builder, here you can find out the most used materials in modular building systems.

There are many different materials are used to make the products. These include:

- Insulated Sandwich Panel Walls:

It could be used in outer or inner walls in modular buildings. The thickness of the walls varies from 50mm to 200mm, and they are optimized for acoustic and thermal performance. The walls are then painted and decorated in various colors and pre-cut with the electric socket, networking, and utility connections in place.

- Quality Galvanized Steel Roof:

The roof in modular building systems is made from high-quality galvanized steel with painted galvanized, gutter-finished sheets or metal tiles.

- Exterior Doors:

The doors are PVC, aluminum, galvanized and painted steel, or metal, depending on the project. They come in various designs and can include additional security bars, locks, or intercom systems.

- Interior Doors:

The interior doors are either aluminum, PVC, or MDF, and fire doors can also be fitted.

- Double-Glazed Windows:

PVC double-glazing or aluminum are the standard choices of windows. Shutters, sunshades, metal security bars, mosquito nets and alarms can all be fitted if necessary.

- Utility and Electric Connections:

Most of modular constructions in modular building systems come pre-manufactured with utility connections. Many options are available, including telephone sockets, electric panels, TV and AV connections, switches, networking, and internet connections.

- Bespoke Additions and Customization:

You can customize your modular construction to include many features. Module-T offers a wide range of bespoke fixtures and fittings to tailor your building to your needs.

Please contact us from here for comprehensive details or to get a Quote.